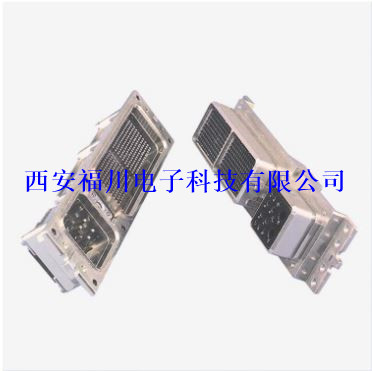

西安福川电子科技有限公司ARINC 600连接器是用于飞机应用的公认标准机架和面板连接器。 ARINC 600是许多新型航空电子设计的ARINC 404的继承者。与ARINC 404相比,ARINC 600具有较低的配合力触点,增加的触点数和前置释放浮动键控系统。 Amphenol广泛的产品将满足客户最苛刻的需求。在设计阶段,Amphenol的销售工程师将与您一起从我们的标准产品系列中选择一个连接器,或协调特定应用连接器的设计。 Amphenol的ARINC 600机架和面板连接器旨在满足所有相关的ARINC 600连接器规格。

特点和好处 西安福川电子科技有限公司

插入力接触低

环境和非环境版本

前可拆卸键控杆

适用于22号和电源触点的现场可更换插件

一个连接器中最多800个尺寸22个触点位置

压接,同轴,电源,印刷电路和绕线触点

波导连接

西安福川电子科技有限公司相关产品

过滤器连接器:

减少检查和装配工作

高频EMI性能优于板级滤波器解决方案

卓越的屏蔽效果

无焊料设计

终止模块

消除连接器暴露于焊接和清洁过程

可轻松修复损坏的插座触点

易于安装和从主板上拆卸有助于维修和返工

路标保证在安装过程中正确对齐

可选的橡胶界面密封保护连接器免受环境影响

底壳

提供应变消除和EMI屏蔽

提供多个电缆入口点

可定制配置

西安福川电子科技有限公司

| PERFORMANCE SPECIFICATIONS | |

| Dielectric withstanding voltage (DWV): | 1500 Vrms, 500 Vms @ 50,000 ft. (15,240m) |

| Contact continuous current ratings: | Size 22 - 5.0A: Size 20 - 7.5A |

| Contact Resistance: | |

| Size 22: | 8.0 milliohms, initial (max.), 11.0 milliohms, conditioned (max.) |

| Size 20: | 7.0 milliohms, initial (max.), 8.5 milliohms,conditioned (max.) |

| Size 16: | 3.5 milliohms, initial (max.), 5.0 milliohms, conditioned (max.) |

| Size 12: | 2.0 milliohms, initial (max.), 2.5 milliohms, conditioned (max.) |

| Insulation resistance: | 5.0 gigaohms min. at 500 VDC |

| Engagement/separation force: | Shell size 1 - 27 Ibs. (120N) max. Shell size 2 - 60 Ibs. (267N) max. Shell size 3 - 105 Ibs. (467N) max. |

| Durability: | 500 cycles min. - mating & unmating |

| Temperature range: | -65°C (-86° F) to +125°C (+275° F) |

| Fluid immersion (Class A only) resistance: | (1) Hydraulic fluid per MIL-H-5606 (2) Lubricating oil (synthetic) per MIL-L-23699 (3) 1:3 mix of isopropyl alcohol & mineral spirits per FED. SPECS. TT-I-735 &TT-T-291 respectively |

| Vibration: | MIL-STD-1344, Method 2005.1, condition value E: random - 16.4G minimum severity: 8 hours in each of 3 mutually perpendicular planes with 100mA electrical load. No visible damage, breakage, cracking or loosening of parts and no discontinuities exceeding 1 microsecond. |

| Shock: | MIL-STD-1344, Method 2004.1, test condition A: Three shocks in each direction along each of 3 axes, mutually perpendicular to each other. No visible damage, breakage, cracking or loosening of parts and no discontinuities exceeding 1 microsecond. |

| MATERIAL SPECIFICATIONS | ||

| Description | Material | Finish |

| Shell and Backshell | Aluminum Alloy or Composite | "Electroless Nickel, Chem Film (Mil-C-5541, Class 3), RoHS Chem Film (MIL-DTL-5541, Type II, Class 3) OD Chromate, Tin, Gold, Zinc Nickel, Yellow CAD or Nickel Fluorocarbon Polymer (Durmalon)" |

| Hardware & Polarizing Keys | Stainless Steel | Passivated or Nickel Plated |

| Inserts | Thermoset or Thermoplastic | -- |

| Aluminum Alloy | Nickel Plated | |

| Grommets & Face Seal | Fluorosilicone Elastomer | -- |

| EMI Spring | Copper Alloy | Nickel Plated, Gold |

| O-Ring | Fluorosilicone Elastomer | -- |

| Contacts | Copper Alloy | Gold over Nickel, Solder Dipping is available in both RoHS and non-RoHS Compliance |